The construction of the complexes lasted more than 2 years.

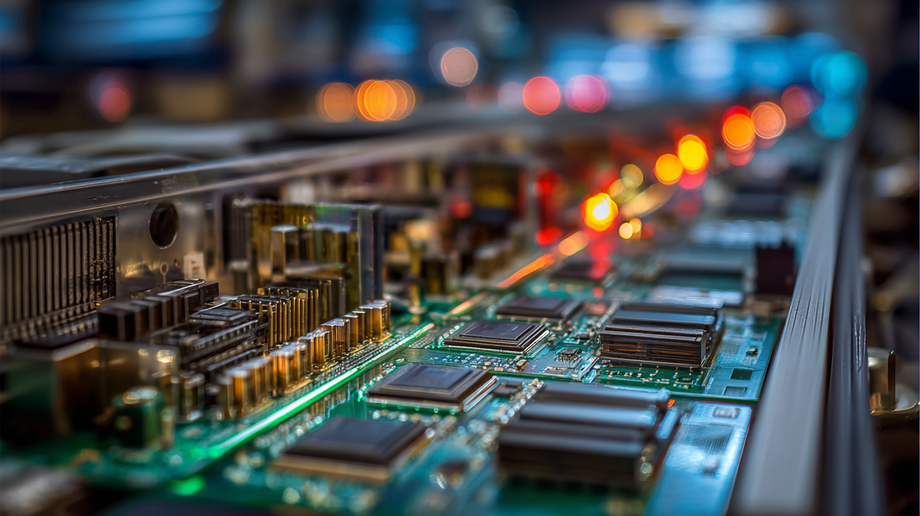

The line at the "Rikor" plant ensures the testing of up to 240 devices per hour, testing the touch panel, keyboard, display, speakers, microphones, camera, fan, fingerprint lock function, and other key components and functions of the device. At the end of the line, "Rikor" laptops undergo 8-hour robotic stress testing using specialized programs, during which maximum performance, heating, and system stability are checked.

Also, the first robotic lines in Russia for the production of metal cases for laptops and servers with a capacity of up to 200 products per hour have been launched at the "Rikor" plant. The new stamping workshop consists of four lines, each of which is equipped with five automated presses and twenty-one robotic manipulators. Additionally, two automated case cutting lines are installed. The production process includes stamping, milling, polishing, sandblasting, anodizing, and control of geometry and surface quality.

Vice President of "Rikor" Group Boris Ivanov said:

The construction of these lines, which have no analogues in Russia, required significant investments and several years of work, but the result is worth it. Now our customers can be sure that they are receiving the highest quality products, in which the possibility of defects is excluded. Robots check each laptop, the cases are made with micron accuracy, while the production cost falls, and deliveries to customers are carried out in the shortest possible time and in batches of any volume.