The Russian market for robotic solutions is demonstrating steady growth. According to a study by the consulting company KSL, in 2025, the proportion of companies planning to invest in deep robotization increased to 8.4% against 4.6% a year earlier. Business is moving to an intensive development model, focusing on optimization and reducing dependence on manual labor.

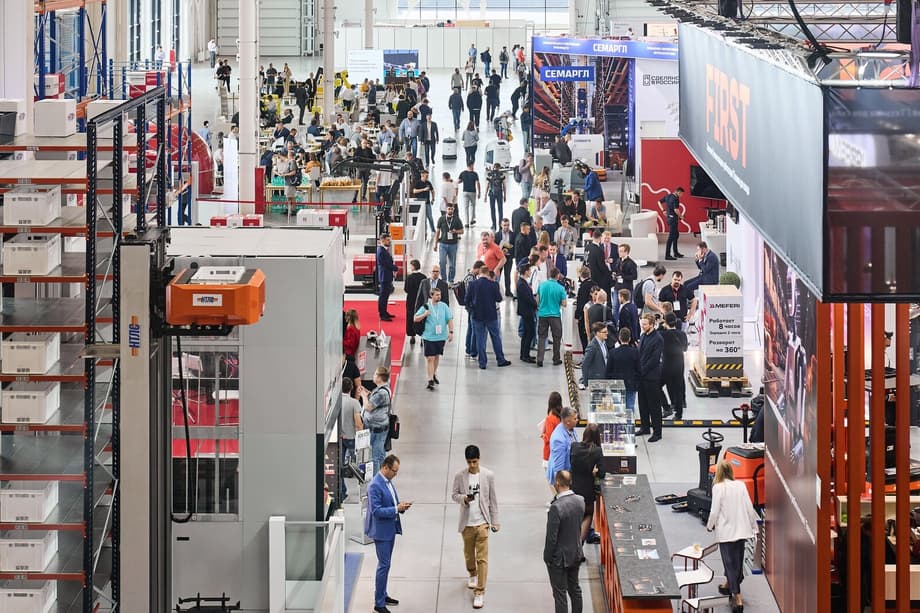

The ReIndustry Expo, held at the Timiryazev Center from June 24 to 26, presented the most sought-after robotic solutions:

AMR robots

AMR robots are mobile platforms for moving goods weighing up to 2 tons. One robot replaces 1-4 employees, with a payback period of 7-9 months. They work with boxes, pallets, and other goods, integrating with other automated systems.

FMR robots

FMR robots are equipped with a forklift for working with pallets. They reduce the need for linear personnel by 70-80%. Manufacturers solve the problem of accurately capturing pallets with stretch film through software.

3D shuttles

3D shuttles provide high-density storage by reducing passages between racks. They increase warehouse capacity by 50-70%, but require significant investment and a long implementation period.

Stacker cranes

Stacker cranes work with goods at a height of up to 40 meters in narrow aisles. The storage density reaches 2.5 m³ per m², and the need for personnel is reduced by 2.5-3 times.

FAST-PICK System

The FAST-PICK system combines ACR and LMR to automate picking. It reduces the number of pickers by 70%, picking errors are reduced by 90-95%, and processing speed increases by 1.5-2 times.

A-Frame sorter

A-Frame sorter is a domestic development for automating the picking of small goods. The system works with vertical channels-cassettes, the productivity reaches 1200 targets per hour or 4000-5000 picking lines. It is especially effective in pharmaceutical warehouses, where up to 50% of all orders pass through the system.

According to Vasily Demin, Executive Director of KSL and organizer of ReIndustry Expo, the exhibition format with demonstration of technologies on stands-training grounds turned out to be effective for the Russian market. Companies were able to evaluate solutions in action and determine their applicability for their tasks. The organizers plan to expand the range of technologies, taking into account the specifics of Russian enterprises.

More than 300 companies have already planned the introduction of robotic solutions in the period 2025-2027, which indicates a growing interest of business in the automation of warehouse processes.