The engineering systems of the Museum Complex in Verkhnyaya Pyshma, one of the world's largest museums of history and technology, have been modernized using advanced technologies and solutions from Systeme Electric, a Russian manufacturer of power distribution and automation equipment.

The Museum Complex, located in the Sverdlovsk region, includes more than 15,000 exhibits of civil and military equipment. Previously, its engineering systems operated on the basis of the foreign Siemens Desigo Insight solution, but after the departure of the foreign vendor from the market, its further maintenance became impractical. In addition, the development of the museum required a cyber-secure solution that would ensure not only the modernization of the existing infrastructure, but also the commissioning of new facilities.

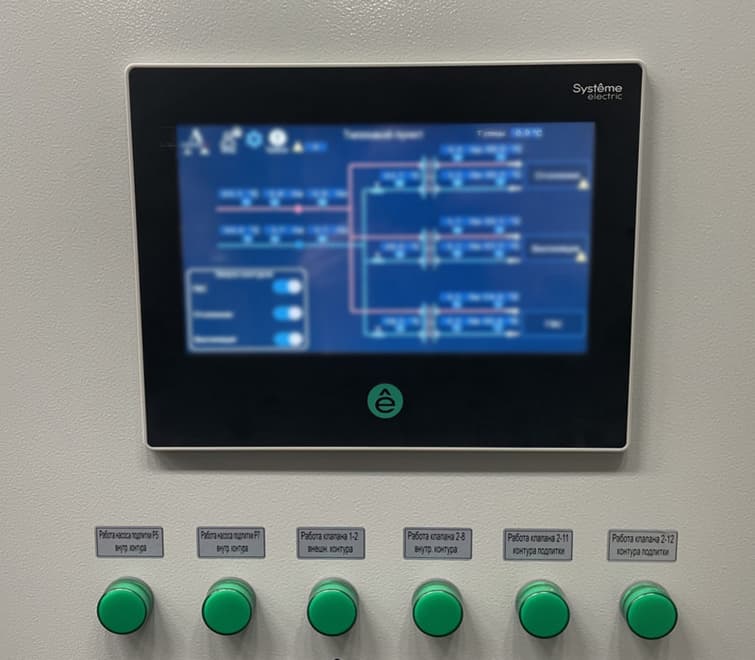

As part of the first phase of modernization of the museum complex's engineering systems, the total area of buildings which exceeds 13,000 sq. m, Systeme Electric solutions were implemented, including SystemeHD programmable BACnet controllers, SystemeHMI operator panels, SystemeSig light signaling system, and SystemeVar frequency converters.

· SystemeHD controllers - used to regulate air parameters, temperature and water pressure, as well as control supply and exhaust ventilation units and heating points.

· SystemeHMI operator panels - provide convenient interaction with equipment and technological processes, support remote access, record events and emergency situations.

· SystemeSig light signaling equipment - features high wear resistance: the service life of electrical components is 1 million cycles, mechanical components - 10 million actuations.

· SystemeVar frequency converters - support operation with asynchronous and synchronous motors, have high overload capacity (up to 200%) and a built-in STO safety function.

One of the key elements of the modernization was the implementation of the domestic SCADA-system Systeme Platform, included in the Register of domestic software of the Ministry of Digital Development of Russia. This made it possible to organize centralized dispatching of the museum complex's engineering systems, providing control, monitoring and management of all technological processes.

This project was implemented with the participation of the engineering company AmpirIT.

Now on home